Manufacturing success requires cutting-edge technology that increase efficiency and agility. Rapid tooling promises to revolutionize production. It uses modern ways to speed up mold, die, and tooling component manufacture. It delivers exceptional speed, cost-effectiveness, and flexibility, unlike conventional technologies with long lead times and rising costs. We discover quick tooling's tremendous impact on automotive, aircraft, consumer electronics, and medical devices. Join us as we explore fast tooling's complex dynamics and its potential to improve manufacturing.

Understanding

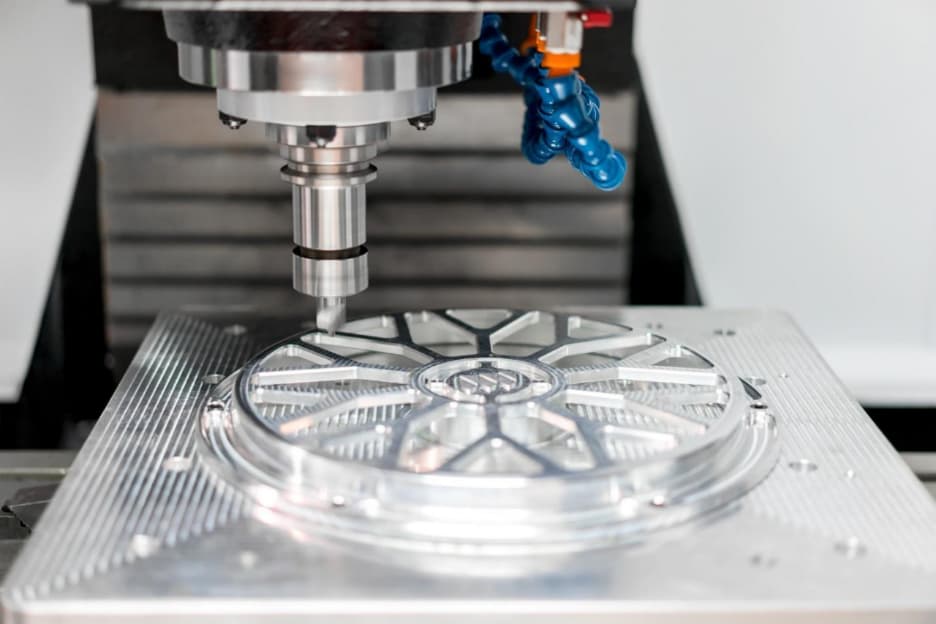

Modern 3D printing and CNC machining speed up mold, die, and tooling component production in it. It speeds manufacturing without sacrificing quality, unlike slower, more expensive procedures. This unique strategy lets companies quickly iterate designs, react to market demands, and expedite production. It helps producers innovate and succeed in today's dynamic market by increasing efficiency and competitiveness.

The Advantages

It is fastest, which is its biggest benefit. It makes working prototypes and tooling components in days, whereas traditional tooling takes weeks or months. This fast turnaround allows manufacturers modify designs quickly, reducing time-to-market and providing them an edge.

It is cheaper than traditional methods. By removing expensive tooling materials and heavy machining, businesses can cut costs without sacrificing quality. Rapid design iteration reduces costly errors, improving cost-effectiveness.

Flexibility: Rapid tooling lets manufacturers respond swiftly to market and design changes. It allows agility and reactivity, helping organizations stay ahead of the curve by altering or generating new ideas.

It maintains quality despite its speed. 3D printing and CNC machining produce precise, high-performance tooling components. Producing items that meet customer expectations requires this quality.

Customization: It allows customization inconceivable with traditional tooling. Tools can be simply customized to meet design needs, enabling innovation and product differentiation. Customized products that appeal to target markets are now possible with this capacity.

Applications Across Industries

It has many industrial uses due to its versatility:

It helps car manufacturers prototype and manufacture complicated parts and components. It can expedite development and speed up innovation for interior trim panels and outside body panels.

It helps aerospace companies create and manufacture lightweight, high-performance components quickly. It improves aircraft performance and efficiency by enabling agility and innovation in engine and structural parts.

It speeds up consumer electronics device development. Quick tooling allows smartphone and wearable makers iterate designs and incorporate new technologies to compete.

It enables device and component customization and manufacturing, transforming the medical device industry. It helps manufacturers meet patient requests for prosthetics and surgical tools, increasing outcomes and quality of life.

Conclusion

Finally, fast tooling boosts production efficiency and innovation. Its speed, cost-effectiveness, and flexibility transform industries. Rapid tooling might change manufacturing as it evolves. This creative method may help companies remain ahead in a changing global economy, adapt to market needs, and grow. It drives change, improving manufacturing efficiency and sustainability.

I am a SEO expert

Post new comment

Please Register or Login to post new comment.